MG Accessories

Ask a question

Got a question?

Enter your question below and we will get back to you as soon as possible.

Description

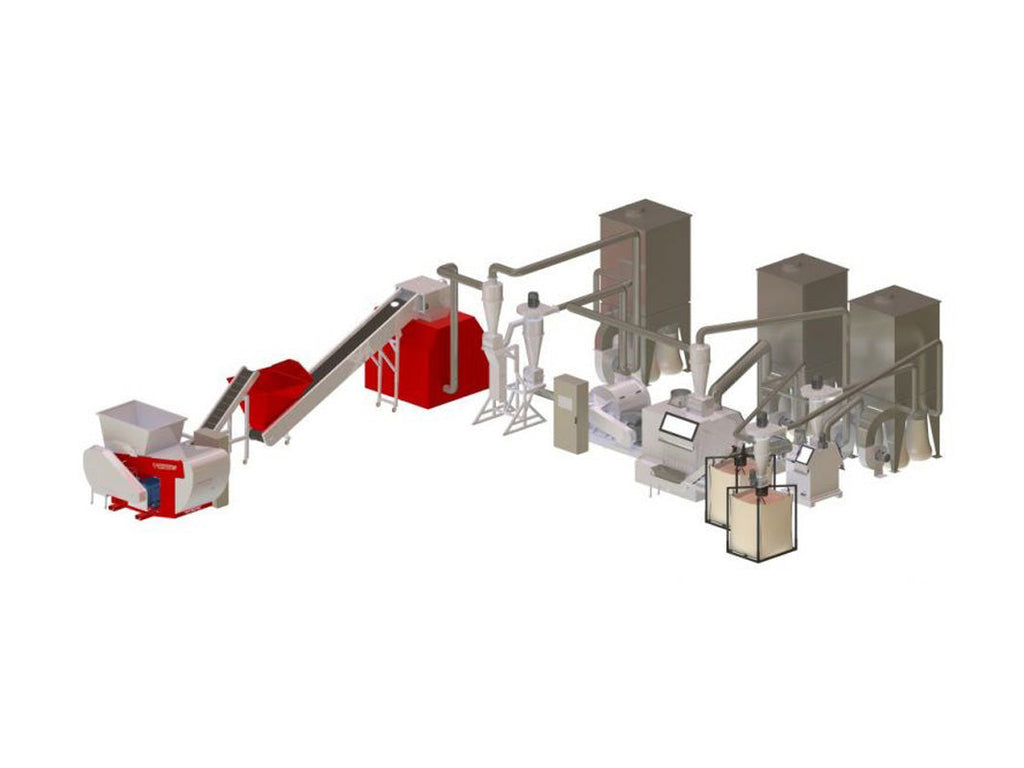

MG Recycling can also custom build a system to suit your needs, with variable capacity of infeed materials from 440lbs an hour up to 6600lbs per hour. The layout of the system can also be designed around your needs as all components can be supplied separately for the system.

MG Recycling Granulators allow the grinding of the processed material, reducing it to the right size for further processing.

MG Recycling Granulators allow the grinding of the processed material, reducing it to the right size for further processing.

The MG Recycling Turbo Mill uses pulverizing technology, running the material through hammers and tooth armors. The material is pulverized, this results in increased production and higher purity through better separation.

The MG Recycling Turbo Mill uses pulverizing technology, running the material through hammers and tooth armors. The material is pulverized, this results in increased production and higher purity through better separation.

MG Recycling’s separation technology is the best in the industry with many patented features. They separate metals from other granulated materials.

MG Recycling’s separation technology is the best in the industry with many patented features. They separate metals from other granulated materials.

MG Recycling’s Vibrating screens allow the full recovery of copper or aluminum dust that is still present in the plastic insulation granules. The vibrating screens can be matched to all the compact systems as well as any of the custom systems.

MG Recycling’s Vibrating screens allow the full recovery of copper or aluminum dust that is still present in the plastic insulation granules. The vibrating screens can be matched to all the compact systems as well as any of the custom systems.

All the MG conveyors are built with a magnetic head roller to remove any ferrous material before it enters the granulator. Alternatively, a cross belt magnet could be supplied. When used with a pre shredder the conveyor speed can be controlled with a signal from the granulator to prevent over feeding and maximize efficient production.

All the MG conveyors are built with a magnetic head roller to remove any ferrous material before it enters the granulator. Alternatively, a cross belt magnet could be supplied. When used with a pre shredder the conveyor speed can be controlled with a signal from the granulator to prevent over feeding and maximize efficient production.

MG Recycling can also include a dosing belt, this is needed when processing wire harnesses to prevent the sticky cover material clogging the granulator.

MG Recycling can also include a dosing belt, this is needed when processing wire harnesses to prevent the sticky cover material clogging the granulator.

The ZIG-ZAG separator is another bit of technology from MG Recycling to allow first separation of the thicker rigid copper or aluminum granules, allowing the operator to run all grades of wire and cable together without the need to pre sort them.

The ZIG-ZAG separator is another bit of technology from MG Recycling to allow first separation of the thicker rigid copper or aluminum granules, allowing the operator to run all grades of wire and cable together without the need to pre sort them.